Products

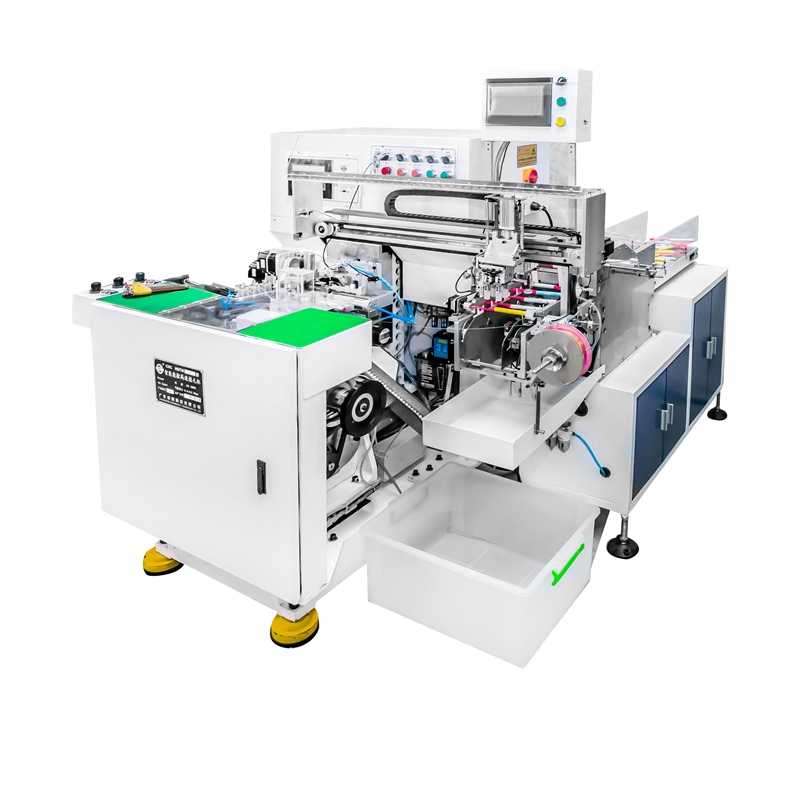

2022 High quality Automatic Blister And Labeling Packaging Machine - High Efficiency Tufting Machine for Toothbrush Making – Chuangyan

2022 High quality Automatic Blister And Labeling Packaging Machine - High Efficiency Tufting Machine for Toothbrush Making – Chuangyan Detail:

Main Feature

The whole model introduced German CNC technology independently developed intelligent CNC scanning hole coordinate touch screen LCD computer servo control system, using Germany IMA, AFG, DURBAL and Japan NSK, IKO and other imported bearings assembly, the introduction of German CNC technology independently developed intelligent CNC scanning hole coordinate touch screen LCD computer, 6 axis Japanese Fuji F6 servo motor Universal fixture and automatic cylinder double pressure Filament feeder, make the equipment strong stability, high repeatable positioning accuracy, easy operation, strong anti-interference ability.

Specification

|

Main technical parameters |

|

|

Machine dimension: 118cmX118cmX140cm |

Equipment speed: 300-840 holes/min |

|

Wooden case size: 28cmX128cmX153cm |

Memory: 400(data) |

|

Net weight: 760KG |

Scan: (Infrared) |

|

Cross weight: 860KG |

Number of filament boxes: 1-3 bits |

|

Input voltage: three-phase 380V 50-60Hz |

Hole diameter: 1.2-3.5MM |

|

Power switch: 20A↑ |

Tufiting length: 50MM |

|

Power: 2.2KW |

Tufiting width: 50MM |

|

Compressed air pressure: 0.5MPa |

Filament material: Petg/pp/AS/PET(ets) |

|

Input air tube: 8MM |

Sheet width: 1.3-1.4MM |

|

Air consumption: ≥1㎡/MIN |

Sheet thickness: 0.25-0.3MM |

|

Noise: 60(db) |

Sheet material: copper, aluminum, iron |

|

Oil tank No.: Xindejia Lubricating Oil No. CC40 |

Filament length: 24-35MM |

|

Equipment use: refer to the manual of tufting macchine |

Filament Dia: 0.08-0.4MM |

|

Filament material: PP/PET/PBT/PA6/PA66(ets) |

|

Detail Information

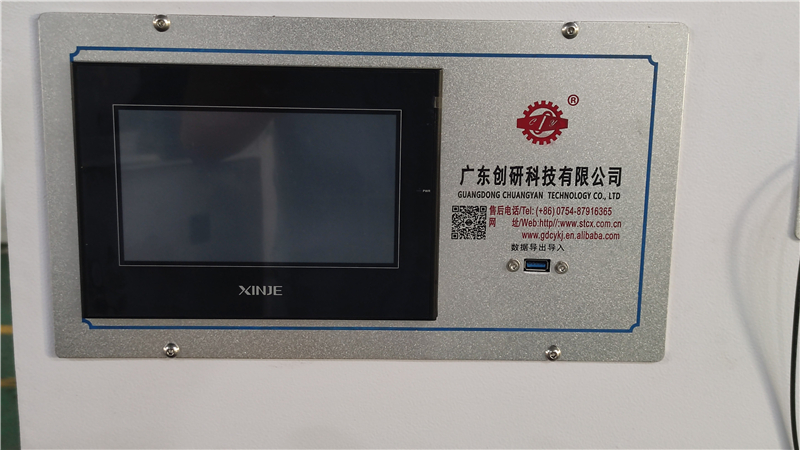

Intelligent CNC Control Computer Part

Features: 1. the introduction of German CNC technology to develop intelligent CNC scanning hole coordinate technology

2. Using American imported CNC CPU chip, P4 dual-core processor

3. Automatic tracking and speed regulation, precise positioning and convenient operation

4. The system is stable and reliable, adapts to different environments, and has strong anti-interference

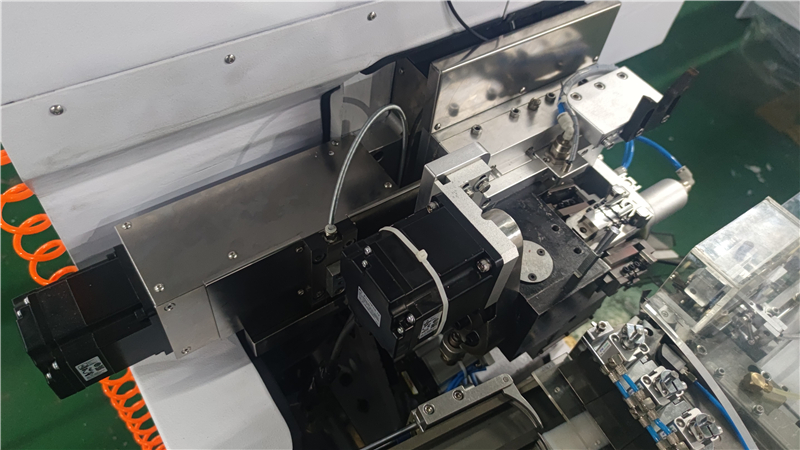

Servo Motor Part Of Worktable And Handle Change

Features: 1. The equipment adopts high-precision servo motors imported from Japan.

2. Adopt German imported precision C1 double threaded ball screw.

3. Designed to never wear,high-precision wear-resistant light rail type, sealed self-lubricating bearings, release the weight of the X-axis table, and achieve 850-speed high-speed tifiting effect.

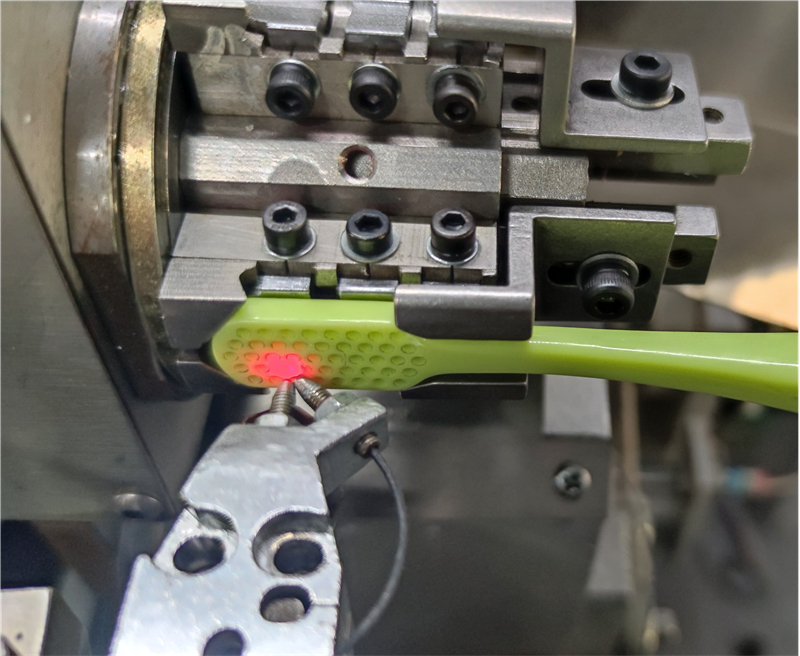

The Coordinate Part Of Auto Scanning

Features: 1. Adopt high-tech infrared automatic scanning toothbrush handle hole coordinates

2. High efficiency changing size, easy to operate, fast and easy to learn

3. High precision of positioning coordinates: tolerance ± 0.02mm

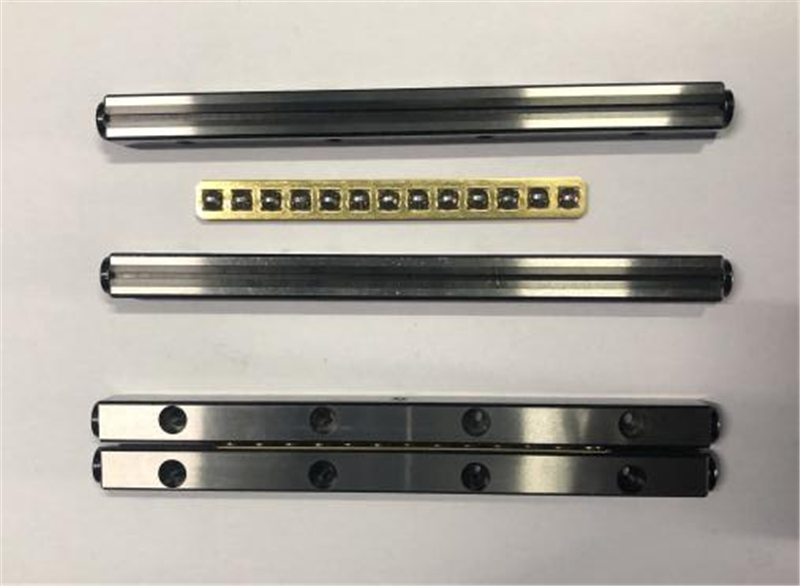

Part Of High Tufting

Features: Adopt Germany imported materials, through professional technology and high precision processing equipment manufacturing tufiting head, hair tufiting knife, tufiting rod, high hardness, good toughness, strong wear resistance, processing technology error ± 0.01mm, so that tufiting stability, high efficiency, strong tension, not loose filament.

Feature: 1. Widening design to ensure the stability of filament volume and increase productivity.

2. Double filament pressing design, pneumatic progressive filament pressing, to ensure high stability of filament picking, no thin filament, no filament spilling.

3. The special metal coating process of hair trough ensures the best product quality.

Product detail pictures:

Related Product Guide:

Gaining purchaser gratification is our firm's intention eternally. We will make wonderful endeavours to build new and top-quality merchandise, satisfy your exclusive needs and provide you with pre-sale, on-sale and after-sale products and services for 2022 High quality Automatic Blister And Labeling Packaging Machine - High Efficiency Tufting Machine for Toothbrush Making – Chuangyan , The product will supply to all over the world, such as: South Africa, Malawi, Orlando, With the development of the society and economy, our company will continue the "loyalty, dedication, efficiency, innovation" spirit of enterprise, and we will always adhere to the management idea of "would rather lose gold, do not lose customers heart". We will serve the domestic and foreign businessmen with sincere dedication, and let us create bright future together with you!

We have been looking for a professional and responsible supplier, and now we find it.

+86754-87916365

+86754-87916365

.png) 13342756672

13342756672