-

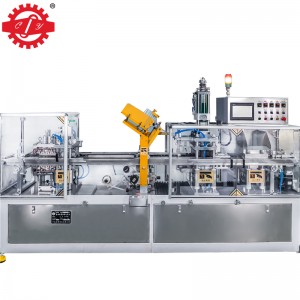

Automatic Blister and Labeling Packaging Machine

Main Feature

The main feature of automatic blister and labeling packaging machine is high efficiency, strong stability, high adjustability, low mold cost, easy replacement, wear and tear, low noise and so on. These features are its advantages. It is also very suitable for environmental protection workshop.

Main Application

This equipment is suitable for packing daily products, stationery, hardware, cosmetics, medicine and other blister packaging. Packaging items such as: toothbrushes, pens, solid glue, lip balm, pen, glue, socket, bearing, brake pads, injections and other packaging, so as to improve the grade of products.

-

Automatic Blister and Labeling Packaging Machine

·Main Feature:

The main feature of automatic blister and labeling packaging machine is high efficiency, strong stability, high adjustability, low mold cost, easy replacement, wear and tear, low noise and so on. These features are its advantages. It is also very suitable for environmental protection workshop.

·Main Application:

This equipment is suitable for packing daily products, stationery, hardware, cosmetics, medicine and other blister packaging. Packaging items such as: toothbrushes, pens, solid glue, lip balm, pen, glue, socket, bearing, brake pads, injections and other packaging, so as to improve the grade of products.

-

Automatic Blister and Labeling Packaging Machine

·Main Feature:

The main feature of automatic blister and labeling packaging machine is high efficiency, strong stability, high adjustability, low mold cost, easy replacement, wear and tear, low noise and so on. These features are its advantages. It is also very suitable for environmental protection workshop.

·Main Application:

This equipment is suitable for packing daily products, stationery, hardware, cosmetics, medicine and other blister packaging. Packaging items such as: toothbrushes, pens, solid glue, lip balm, pen, glue, socket, bearing, brake pads, injections and other packaging, so as to improve the grade of products.

-

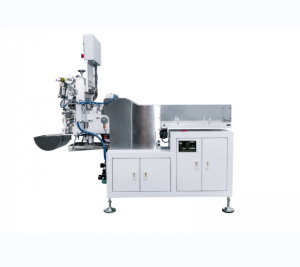

Pneumatic Filament Cutting Machine

Introduction:

The equipment is composed of mechanical structures such as frame, material rack, tool holder, and limit holder. Place the brush filament in the material rack, feed the material to the limited position, and cut out the required brush filament length. Its capacity is about 300 kilograms of filaments per hour.

Main Application:

Suitable for all kinds of brush filaments, such as: toothbrush filaments, cosmetic brush filaments, industrial brush filaments,etc., and can cut the filaments to the required length.

-

High Efficiency Manipulator for Toothbrush

设备特点Equipment Features:

1.本设备采用德国IMA,AFG,DURBAL,和日本NSK,IKO等各种进口轴承组装。

This equipment adopts IMA,AFG,DURBAL, Japan NSK,IKO and all kinds of imported bearings assembly.2.引进德国CNC技术和6轴CNC德国设备,配件一体化完成,精密度更高。

It introduces German CNC technology and 6-axis CNC equipment from Germany, and the accessories are integrated with higher precision.3.邀请日本富士工程师协助,自主研发的操作系统,人性化设计,操作简便, 稳定性强。

It invites Japan Fuji engineers to assist, with independent research and development of the operating system, humanized design, simple operation and strong stability.设备适用对象 Equipment Applicable Objects:

适用于各种刷类。物品如:牙刷,化妆刷,工业刷等各种刷类。

Suitable for various brush, such as toothbrush, cosmetic brush, industrial brush and other brush.设备用途 Equipment Use:

代替人工操作,自动为植毛机送料

Replacing manual operation, automatically feeding the wool planting machine设备原理 Equipment Principle:

把刷类放于设备料斗上,依次经过搓板、对中、称重、放行、掉头、翻面、烫金等机械装置,送至植毛机工作台上。

Place the brushes on the equipment hopper, pass through mechanical devices such as washboard, centering, weighing, release, turning, flipping, and stamping, and then deliver them to the working table of the hair planting machine. -

Automatic Toothbrush Trimming Machine for Toothbrush Making

Main Application:

Suitable for all kinds of brushes, such as: toothbrushes, cosmetic brushes, industrial brushes, etc. It can cut and grind the filaments of various brushes, such as toothbrushes, cosmetic brushes, and industrial brushes, to obtain the desired effect of the product.

Introduction:

The equipment consists of various mechanical structures such as frame, active chain, intermittent gear box, main motor, transmission chain, reduction box, passive sprocket, fixture, cutting knife, moving head seat, grinding disc, grinding disc motor, control box, suction box, etc. composition. As long as put the brushes in the jig, and pass through the cutting knife, grinding disc, dust removal, unloading and other mechanical devices in turn to produce the desired effect of the product. Its capacity is about 36,000 pcs per 12 hours (capacity is provided for reference only, the actual production capacity is adjusted according to the product effect).

-

Hot Foil Stamping Machine for Toothbrush Production Line

Main Application:

It apply to various brush, such as toothbrush, cosmetic brush and industrial brush, etc. and process the Logo required by these brushes.

Introduction:

The equipment consists of frame, hopper, washboard, centering, weighing, releasing, turning, flipping, hot stamping and other mechanical structures. As long as put the brush on the mechanical devices, it can automatically process the Logo required by the brush. Its capacity is about 2000pcs per hour. (Capacity is for reference only, actual capacity according to product effect to adjust speed.)

-

Automatic Tufting and Trimming Machine with All-in-one

Introduction:

The whole machine is composed of four kinds of equipment, including tufting machine, handle feeder machine, timming machine, and vacuum cleaner, into a fully automatic toothbrush tufting & timming machine. Among them, the tufting machine is composed of various mechanical structures such as a base, a moving table, a servo electric appliance, a scanner, a main motor, a transmission wheel, a cam, three-color filament box, a feeding device, a filament feeding device, and a high-speed tufting device. The tufting machine is composed of frame, bucket, washboard, weighing, feeding, U-turn, turning, main arm and other structures. The timming machine is composed of a frame, a main motor, a disc, a fixture, a hair cutting knife, a grinding disc, dust removal and static electricity removal, and servo electrical appliances.

The machine adopts the mechanical structure of feeding toothbrush handle and send them to the tufting machine for tufting filament automatically. Filament feeding box, tufting device and other mechanical linkage work, brush handle here to complete tufting process, then toothbrush than send them to trimming machine by the mechanical arm for grinding filament, the working process is to produce the desired effect of the product by means of cutting knife and grinding plate and remove electrostatic and finished product move device. Its capacity is about 8,000-25,000 pieces per 12 hours.

-

High Efficiency Tufting Machine for Toothbrush Making

Main Application:

The machine is suitable for all kinds of brushes, such as: toothbrushes, cosmetic brushes, industrial brushes and other brushes, to apply required brush filaments for various types of brushes.

Introduction:

The equipment is composed of various mechanical structures, such as frame, mobile platform, servo electrical appliance, scanner, main motor, transmission wheel, CAM, wool box, feeding device, wire feeding device, high-speed hair planting device and so on. Put the toothbrush handle on the workbench, and put filament in the filament feeder, using the transmission wheel, CAM, mobile platform, filament feeder, wire feeding device, feeding device, high-speed filament tufting device and other mechanical structures, the brush wire in the brush, produce the desired effect of the product. Its capacity is about 8,000-25,000 pieces per 12 hours.

-

High Speed Tufting Machine in Toothbrush Production Line

The whole model introduced German CNC technology independently developed intelligent CNC scanning hole coordinate touch screen LCD computer servo control system, using Germany IMA, AFG, DURBAL and Japan NSK, IKO and other imported bearings assembly, the introduction of German CNC technology independently developed intelligent CNC scanning hole coordinate touch screen LCD computer, 6 axis Japanese Fuji F6 servo motor Universal fixture and automatic cylinder double pressure Filament feeder, make the equipment strong stability, high repeatable positioning accuracy, easy operation, strong anti-interference ability.

The machine is suitable for all kinds of brushes, such as: toothbrushes, cosmetic brushes, industrial brushes and other brushes, to apply required brush filaments for various types of brushes.

-

Automatic High Speed Toothbrush Tufting Machine

Short Description:

Main Application:The machine is suitable for all kinds of brushes, such as: toothbrushes, cosmetic brushes, industrial brushes and other brushes, to apply required brush filaments for various types of brushes.

Introduction:

The equipment is composed of various mechanical structures, such as frame, mobile platform, servo electrical appliance, scanner, main motor, transmission wheel, CAM, wool box, feeding device, wire feeding device, high-speed hair planting device and so on. Put the toothbrush handle on the workbench, and put filament in the filament feeder, using the transmission wheel, CAM, mobile platform, filament feeder, wire feeding device, feeding device, high-speed filament tufting device and other mechanical structures, the brush wire in the brush, produce the desired effect of the product. Its capacity is about 8,000-25,000 pieces per 12 hours.

-

High Precision Tufting Machine for Toothbrush Making

The whole model introduced German CNC technology independently developed intelligent CNC scanning hole coordinate touch screen LCD computer servo control system, using Germany IMA, AFG, DURBAL and Japan NSK, IKO and other imported bearings assembly, the introduction of German CNC technology independently developed intelligent CNC scanning hole coordinate touch screen LCD computer, 6 axis Japanese Fuji F6 servo motor Universal fixture and automatic cylinder double pressure Filament feeder, make the equipment strong stability, high repeatable positioning accuracy, easy operation, strong anti-interference ability.

The machine is suitable for all kinds of brushes, such as: toothbrushes, cosmetic brushes, industrial brushes and other brushes, to apply required brush filaments for various types of brushes.

+86754-87916365

+86754-87916365

.png) 13342756672

13342756672