Products

Automatic Toothbrush Trimming Machine for Toothbrush Making

Video

Main Feature

● This equipment introduces advanced German circular grinding technology, high efficiency, high quality, ultra-stable, ultra-speed, quick replacement of products and other advantages, using CAD computer-aided design and manufacturing.

● Two cutting platforms make the cutting quality more stable.

● High-precision fully enclosed steel bridge, after heat treatment, grinding surface, high hardness, not easy to wear.

● Designed with 54 precision fixtures for brush handle, the efficiency can reach 2000pcs per hour.

● Eight positive and negative cone swing rotary imported diamond grinding discs, and a fully enclosed grinding disc suction cover.

● Six-stage frequency conversion adjustable round sharpening treatment effect, automatic timing of dust and air jet.

Specification

|

Basic parameters |

Main technical parameters |

|

Machine dimensions: 237cmX68cmX123cm |

Timming speed: 20-60pcs/min |

|

Vacuum cleaner dimension: 110cmX64cmX188cm |

Working length: 45MM |

|

Case1: 247cmX72cmX150cm(machine) |

Working width: 18MM |

|

Case2: 117cmX70cmX150cm(Vacuum cleaner) |

Working depth: 10MM |

|

Net weight: 750KG+100KG |

Feeding station: 5 bits |

|

Cross weight: 850KG+170KG |

Nunber of cutting knife: 2(pcs) |

|

Electric supply: three-phase four-wire 380V 50-60Hz |

Brush filament length by eye: 4MM-15MM |

|

Switch power: 32A↑ |

Number of timming disc: 8 |

|

Power: 4.5KW |

Timming disc speed: 2800 RPM |

|

Air compressor: 0.4MPa |

Timming rate: flat 95%↑, wave 90%↑ |

|

Input air tube: 8MM |

Input electric for vacuum: 380V-50HZ |

|

Air consumption: ≥0.5㎡/MIN |

Vacuum power: 3.5KW |

|

Gear oil: (New Dejia)CC40 |

Vacuum consumption: 3200m3/h |

|

Turbine oil: (New Dejia gear oil)L-CKD220 |

Noise: 65(db) |

|

Lubricating grease: 7014-1(The Great Wall High Temperature Grease) |

Detail Information

Circular Grinding Treatment

Features: 1. Omni-directional spherical surface treatment, grinding rate can reach more than 85%

2. The grinding disc is plated with high-quality imported diamond grains, with fine material, strong toughness and good wear resistance

3. Fully enclosed dust hood, automatic timing air jet, centrifugal dust removal to remove static electricity

4. 3.5KW large flow centrifugal dust collector

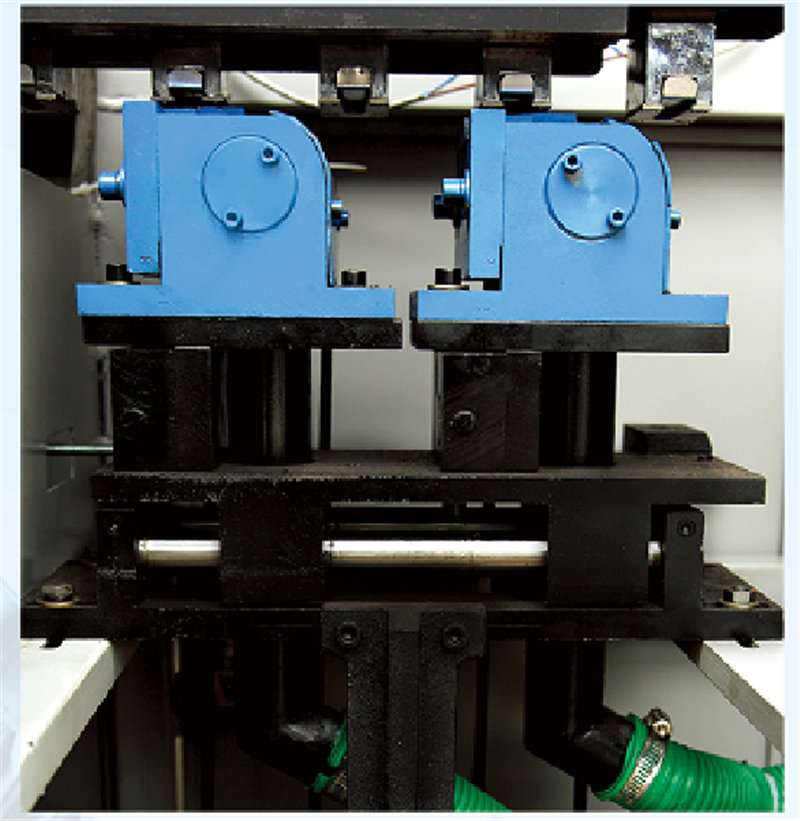

Main Mechanism

Features: High-precision fully enclosed steel bridge, after heat treatment, grinding surface, high hardness, not easy to wear.

Cutting Device Part

Features: 1. Using German cutting technology, high precision and wear resistance

2. Imported precision linear bearing tracks, wear-resistant

3. The cutting knife and the knife holder are integrated, with strong stability and high precision

4. Precise fine-tuning of flat hair length adjustment, convenient and quick

+86754-87916365

+86754-87916365

.png) 13342756672

13342756672