-

High Efficiency Injection Molding Machine for Toothbrush

Injection molding machine also known as injection molding machine or injection machine. It is the thermoplastic or thermosetting material using plastic molding mold into plastic products of various shapes of the main molding equipment. The main feature of injection molding machine is high efficiency, strong stability, high adjustability, low mold cost, easy replacement, wear and tear, and so on. It can also reduce the use of electricity, in the ideal working condition of electricity saving efficiency is relatively high. These features are its advantages. It is also very suitable for environmental protection workshop.

-

Customized Toothbrush Mould with Good Quality

Mould is used in industrial production for injection molding, blow molding, extrusion, die casting or forging molding, smelting, stamping and other methods to get the required products of various mould and tools. Mould is a precision tool, complex shape, bear the billet expansion force, the structural strength, stiffness, surface hardness, surface roughness and processing accuracy have higher requirements. The development level of mould production is one of the important signs of mechanical manufacturing level in this era. In short, a toothbrush mould is a tool used to make a molded toothbrush and it is made up of a variety of parts. The mould has a specific profile or cavity shape, and the blank can be separated according to the profile shape by using the profile shape with a cutting edge. This kind of toothbrush mould has high precision, high stability and long service life. It can be customized, according to samples, drawings and customer specific requirements, so as to produce a high precision mould, to meet customer’s personalized needs.

-

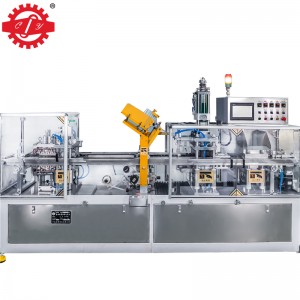

High Efficiency Automatic OPP Packing Machine for Toothbrush

Main Feature:

OPP packaging machine is the heat shrink packaging machine equipment is more advanced, a high degree of automation of a product. The product is suitable for film sealing and heat shrinkable packaging. It can automatically feed film, automatic bag making, surface smoothing, sealing and cutting film packaging, heat shrink packaging at one time. At the same time, the waste can be recycled. Its cutter is made of constant temperature aluminum alloy, specially made for OPP diaphragm sealing and cutting. The characteristic of the cutter is that the sealing line is relatively thin, anti – stick. In addition, it can be adjusted in a certain range for different sizes of packages without replacing grinding tools. At the same time can be manually adjusted parts of the heat shrinkable furnace temperature and speed of heat shrinkable packaging.Main Application:

This equipment is suitable for packing daily products, stationery, hardware, cosmetics, medicine and other blister packaging. Packaging items such as: toothbrushes, pens, solid glue, lip balm, pen, glue, socket, bearing, brake pads, injections and other packaging, so as to improve the grade of products. It adopts color touch screen and stable and reliable dual-axis high-precision output PLC control, bag making, measuring, filling, sealing, coding, cutting bag once completed.Selling Point:

1.side open protective baffle with good visibility, safe operation

2.with high automatic grade, high efficiency and high stability

3.clean, sanitary, energy saving, using OPP packaging machine clean and sanitary, and no longer need manual work

1 基 本 参 数

Machine Data

电压Voltage: 230V

最大功率Maximum Power: 2.1KW

整机尺寸Whole machine size: 680mm X 1120mm

台面高度Table height: 920mm

机器重量Machine weight: 70kg

最大产品高度Maximum product height: 200mm

Main Part:

recision

2. High precision and high stability

-

High Precision Blister Labeling and Packing Machine for Toothbrush

Main Feature

The main feature of automatic blister and labeling packaging machine is high efficiency, strong stability, high adjustability, low mold cost, easy replacement, wear and tear, low noise and so on. These features are its advantages. It is also very suitable for environmental protection workshop.

Main Application

This equipment is suitable for packing daily products, stationery, hardware, cosmetics, medicine and other blister packaging. Packaging items such as: toothbrushes, pens, solid glue, lip balm, pen, glue, socket, bearing, brake pads, injections and other packaging, so as to improve the grade of products.

-

New Era High Efficiency Mask Machine with

Main Application:

It mainly used for automatic forming of disposable masks, and can make masks for adults and children.

Main Application

1. Can make adult and kids mask both.

2. The ear band can be inner folded automatically.

3. Automatic detection of the position and length of the nose wire.

4. Can be connected with automatic packaging machine to make 1-10 pcs/pack.

-

High Performance Automatic OPP Packing Machine

OPP packaging machine is the heat shrink packaging machine equipment is more advanced, a high degree of automation of a product. The product is suitable for film sealing and heat shrinkable packaging. It can automatically feed film, automatic bag making, surface smoothing, sealing and cutting film packaging, heat shrink packaging at one time. At the same time, the waste can be recycled. Its cutter is made of constant temperature aluminum alloy, specially made for OPP diaphragm sealing and cutting. The characteristic of the cutter is that the sealing line is relatively thin, anti – stick. In addition, it can be adjusted in a certain range for different sizes of packages without replacing grinding tools. At the same time can be manually adjusted parts of the heat shrinkable furnace temperature and speed of heat shrinkable packaging.

+86754-87916365

+86754-87916365

.png) 13342756672

13342756672