Products

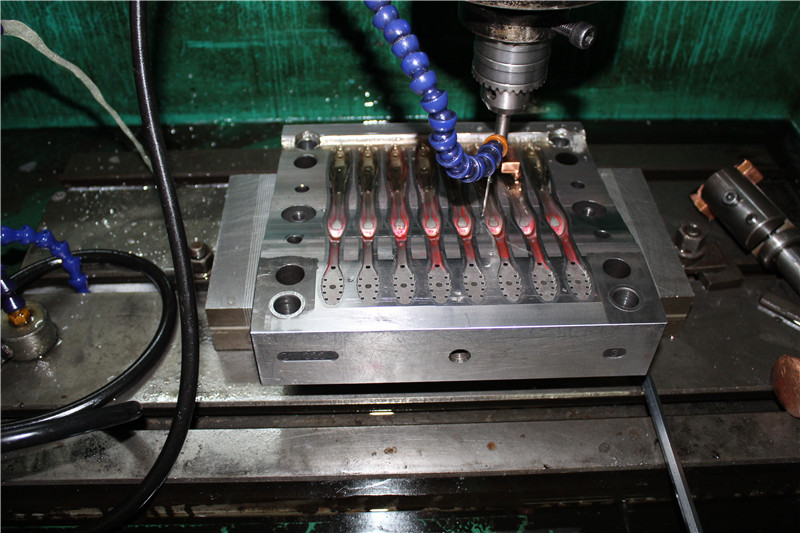

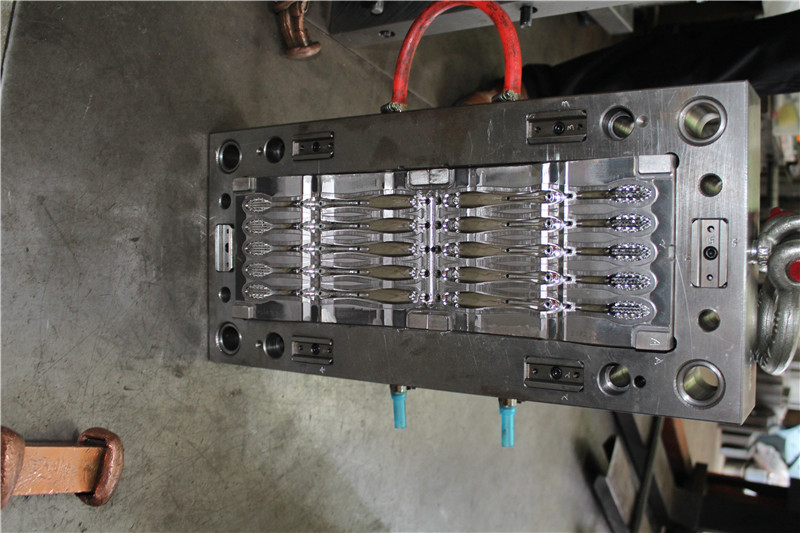

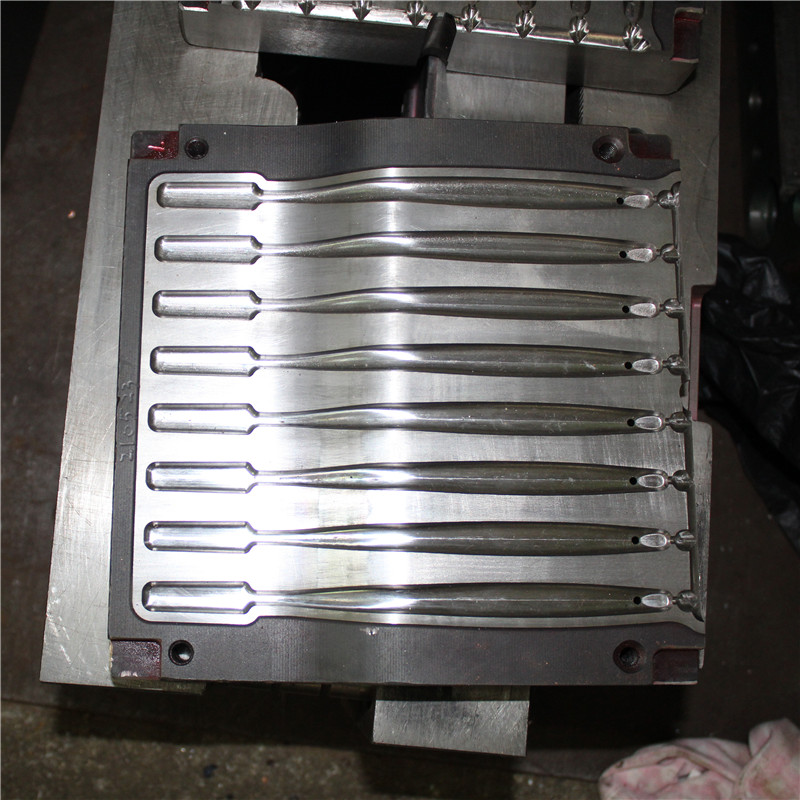

Customized Toothbrush Mould with Good Quality

Main Application

This mould is suitable for making all minds of ordinary toothbrush. By injection molding, blow molding, extrusion, die casting or forging molding, smelting, stamping and other methods to get the required toothbrush. It is under the action of external forces to make the blank into a specific shape and size of the tool. Mould is a high precision tool. It with complex shape, can bear the billet expansion force, the structural strength, stiffness, surface hardness, surface roughness and processing accuracy have higher requirements.

Introduction

● Be able to custom toothbrush plastic injection mould with good quality

● Provide high quality custom toothbrush plastic injection molded parts

● Product toothbrush with high precision and high rigidity

● Toothbrush mould can be customized to the specific shape and size required

Detail Information

Main Part

Feature: 1. Synchronous positioning, high precision

2. High precision and high stability

+86754-87916365

+86754-87916365

.png) 13342756672

13342756672