Products

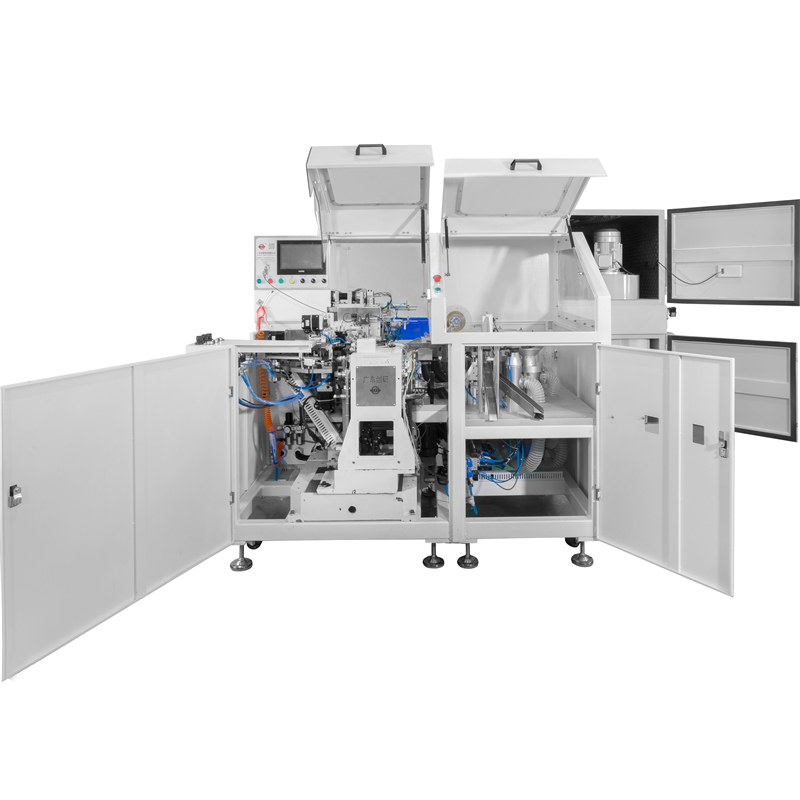

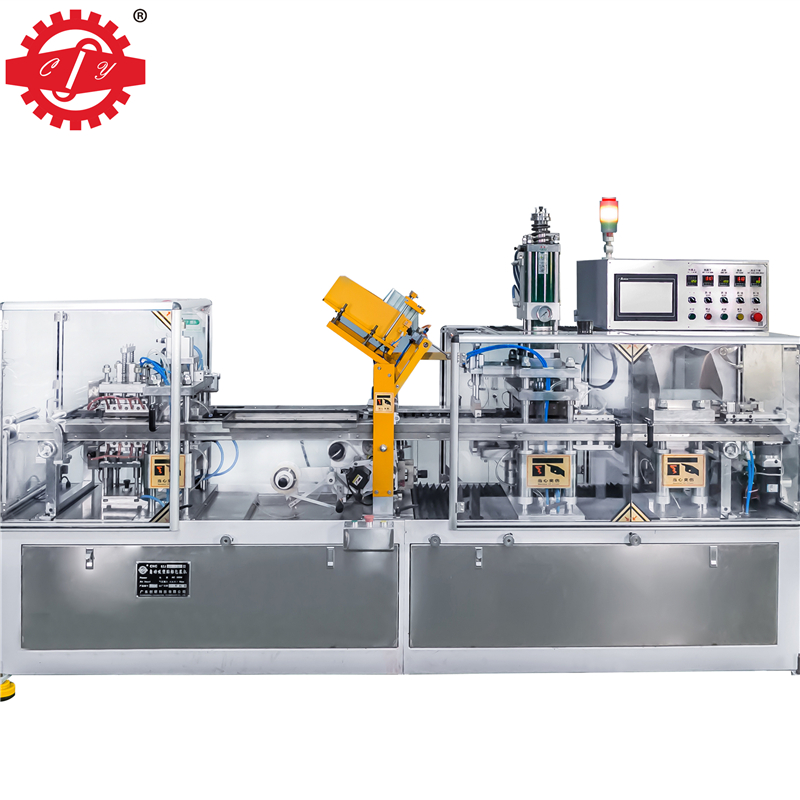

Manufacturer for Tool Grinding Machine - Automatic Tufting and Trimming Machine with All-in-one – Chuangyan

Manufacturer for Tool Grinding Machine - Automatic Tufting and Trimming Machine with All-in-one – Chuangyan Detail:

Main Application

The machine is suitable for all kinds of brushes, such as: toothbrushes, cosmetic brushes, industrial brushes and other brushes. It used for the brush filaments required for various types of brushes.

Main Feature

● Machine is used with various imported bearings from Germany IMA, AFG, DURBAL and Japan NSK, IKO, so that the quality of the equipment is guaranteed.

● Introduce German CNC technology to independently research and develop an intelligent numerical control face-sweeping coordinate touch screen LCD computer, and Japan’s Fuji four-axis original servo motor, which makes the equipment stable, high precision of repeated positioning, convenient operation, and strong anti-interference ability.

● Fully-automatic feeder handle device, real universal fixture, mechanical arm link, so that the production and operation of the equipment can save costs, and it is easy to adjust and change models.

● The design of double trimming knives in the grinding process is suitable for the design and production of various product shapes.

● Eight-level omnidirectional positive and negative cone swing type and imported diamond grinding disc, so that the ratio of grinding and rounding is more than 90% higher than that of the national standard.

●Design automatic de-static dust removal device

● Reserve mechanical space to prepare a prerequisite for special product design actions (such as the product in the video, which has an automatic feeding function designed to save labor costs)

Specification

|

Basic parameters of |

|

|

Host size: 197cmX245cmX157cm |

Vacuum size:105cmX84cmX196cm |

|

(host)Wooden case size: 200cmX250cmX190cm |

(vacuuming)Wooden case size: 90cmX110cmX205cm |

|

Net weight: 1180KG+220KG |

Cross weight: 1420KG+280KG |

|

Disassembly size1: 131cmX244cmX157cm |

Disassembly size2: 108cmX133cmX157cm |

|

Input voltage: three-phase 380V 50-60HZ |

Power switch: 32A↑ |

|

Power: 7KW |

Compressed air pressure: 0.65MPa |

|

Intake pipe: 12MM |

Air consumption: ≥1㎡/MIN |

|

Noise: 65 (dB) |

|

|

Tank No.: Xindejia Lubricating Oil No. CC40 |

Equipment use: refer to the manual and equipment operation video |

Detail Information

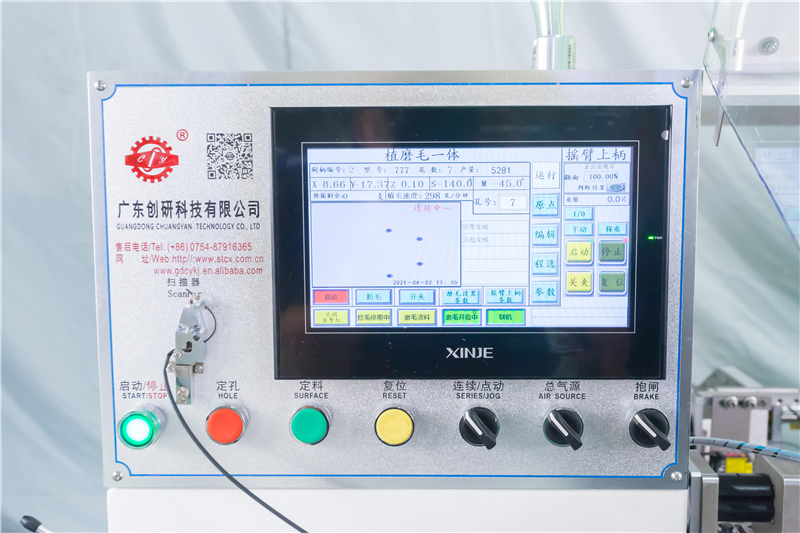

Intelligent Cnc Control Computer Part

Features: 1 the introduction of German CNC technology to develop intelligent CNC scanning hole coordinate technology

2. Using American imported CNC CPU chip, P4 dual-core processor

3. Automatic tracking and speed regulation, precise positioning and convenient operation

4. The system is stable and reliable, adapts to different environments, and has strong anti-interference

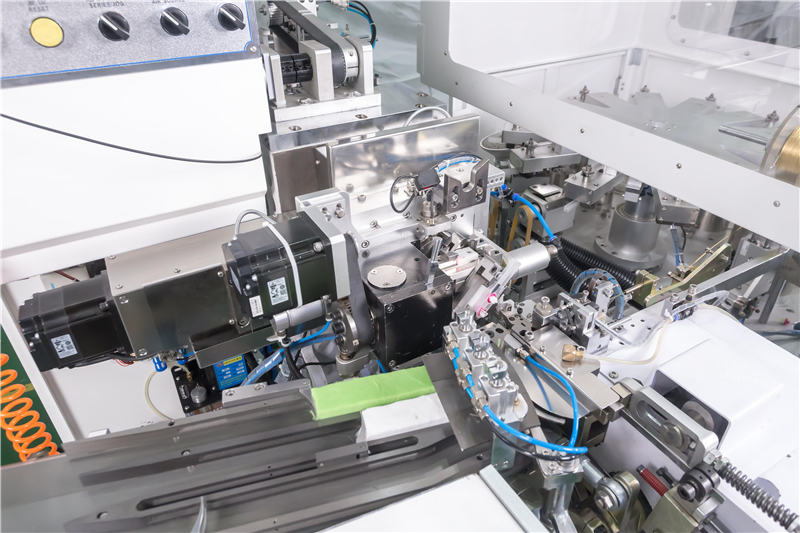

Servo Motor Part Of Worktable And Handle Change

Features: 1. The equipment adopts high-precision servo motors imported from Japan

2. Adopt German imported precision C1 double threaded ball screw

3. Designed to never wear, high-precision wear-resistant light rail type, sealed self-lubricating bearings, release the weight of the X-axis table, and achieve 850-speed high-speed tufting effect

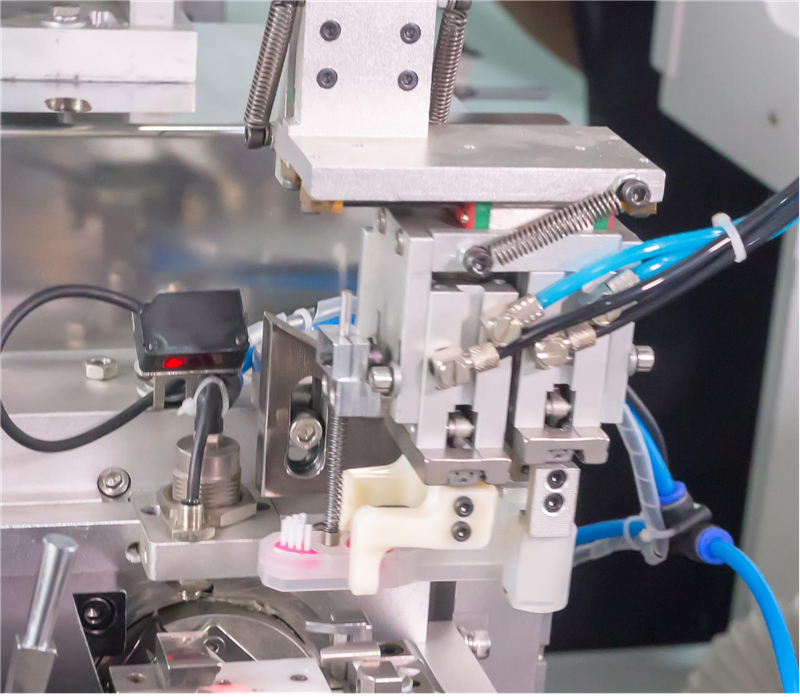

The Coordinate Part Of Auto Scanning

Features: 1. Adopt high-tech infrared automatic scanning toothbrush handle hole coordinates

2. High efficiency changing size, easy to operate, fast and easy to learn

3. High precision of positioning coordinates: tolerance ± 0.02mm

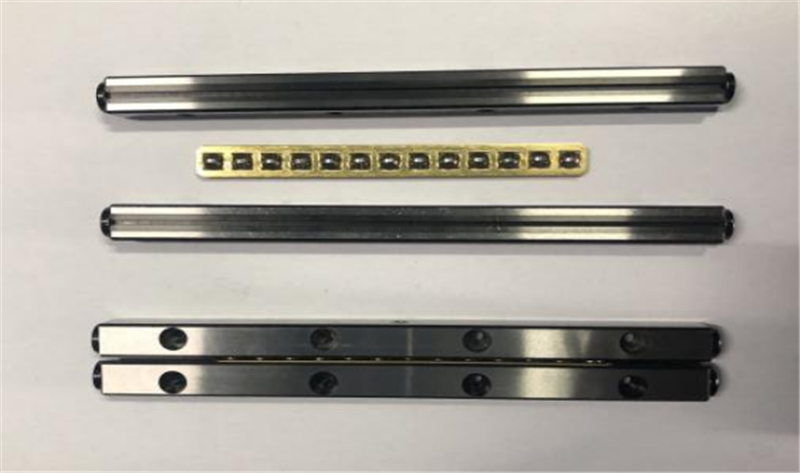

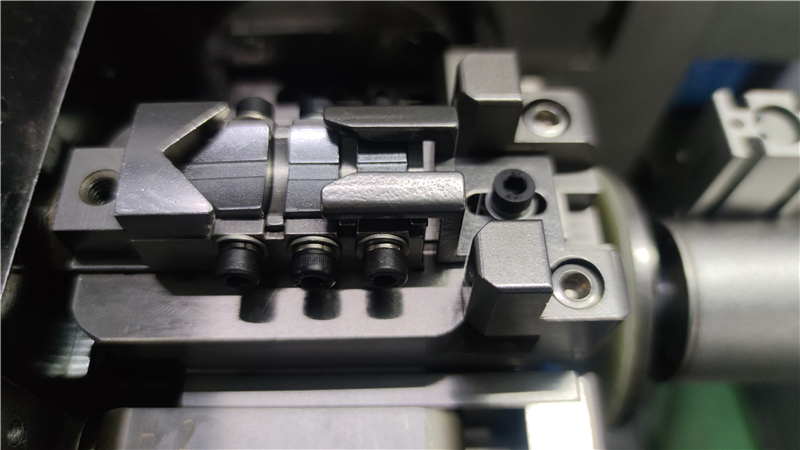

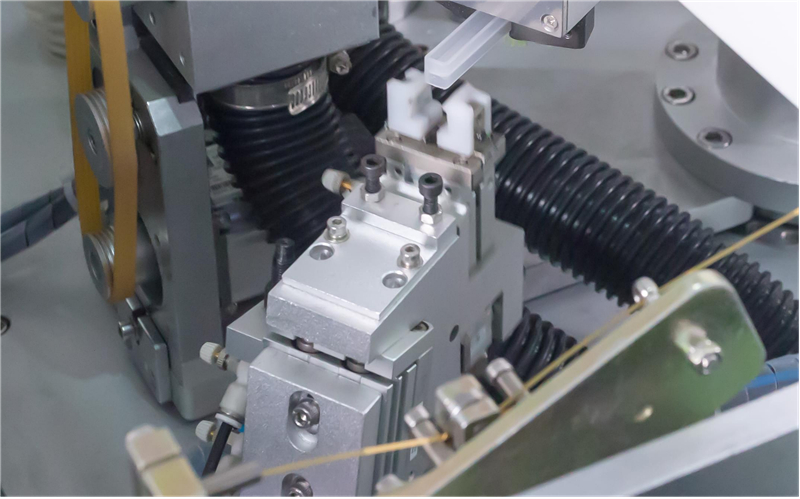

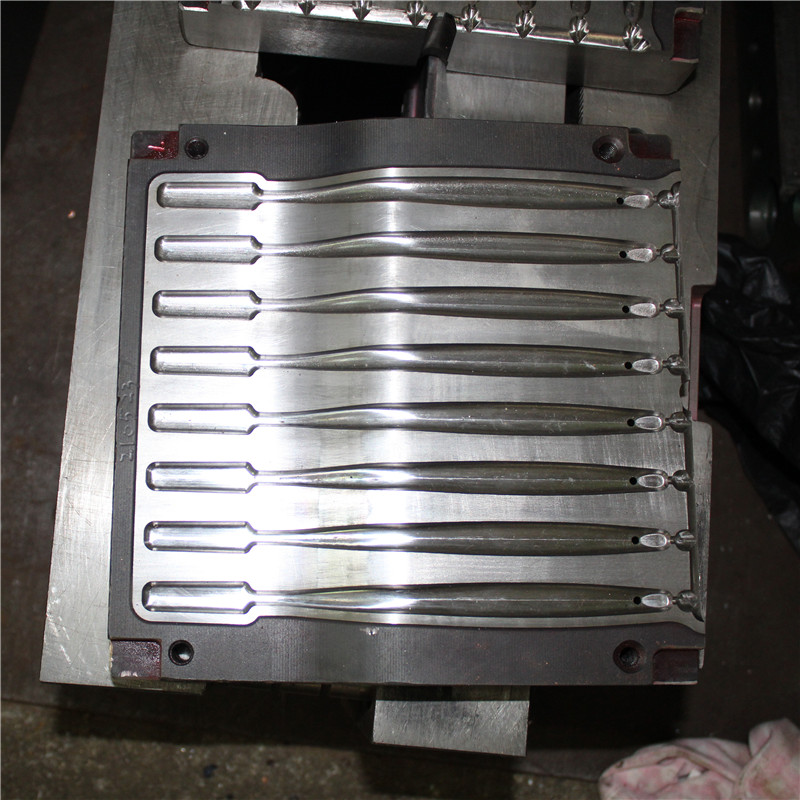

Part Of High Tufting

Features: Adopt Germany imported materials, through professional technology and high precision processing equipment manufacturing tufting head, hair tufting knife, tufting rod, high hardness, good toughness, strong wear resistance, processing technology error ± 0.01mm, so that tufting stability, high efficiency, strong tension, not loose filament

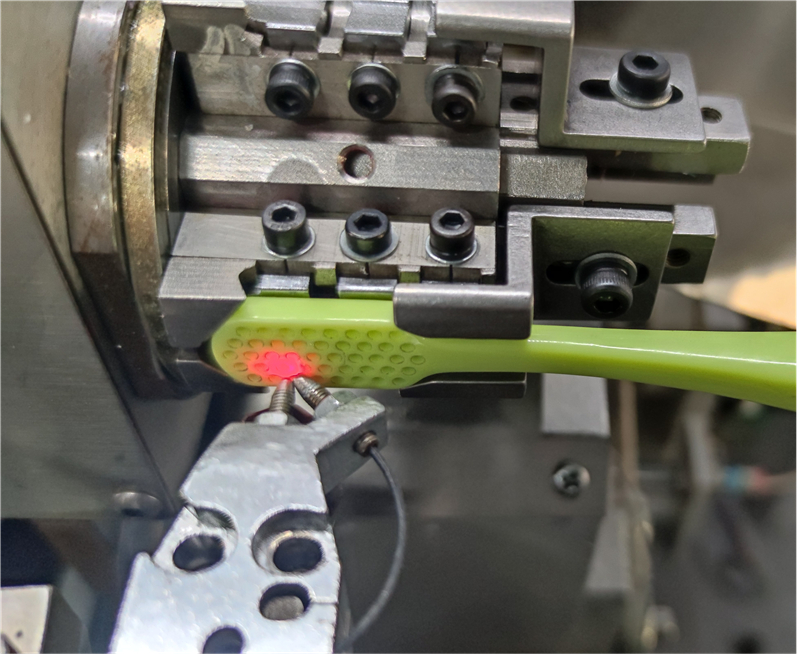

Universal Fixture

Feature: The universal fixture in the true sense, and can plant all kinds of electric toothbrush without tailings, without each product customized fixture or special products can not be produced

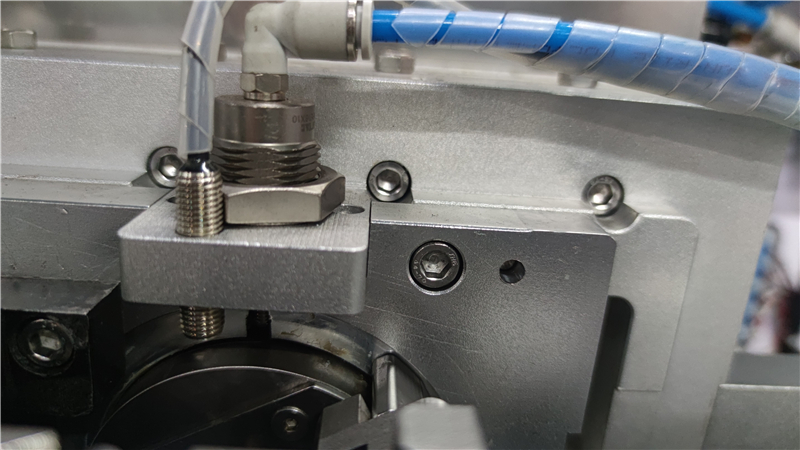

Rotating Shaft

Feature: High precision direct connection rotating Z axis (no need to replace the belt)

Feature: 1. Widening design to ensure the stability of filament volume and increase productivity

2. Double filament pressing design, pneumatic progressive filament pressing, to ensure high stability of filament picking, no thin filament, no filament spilling

3. The special metal coating process of hair trough ensures the best product quality

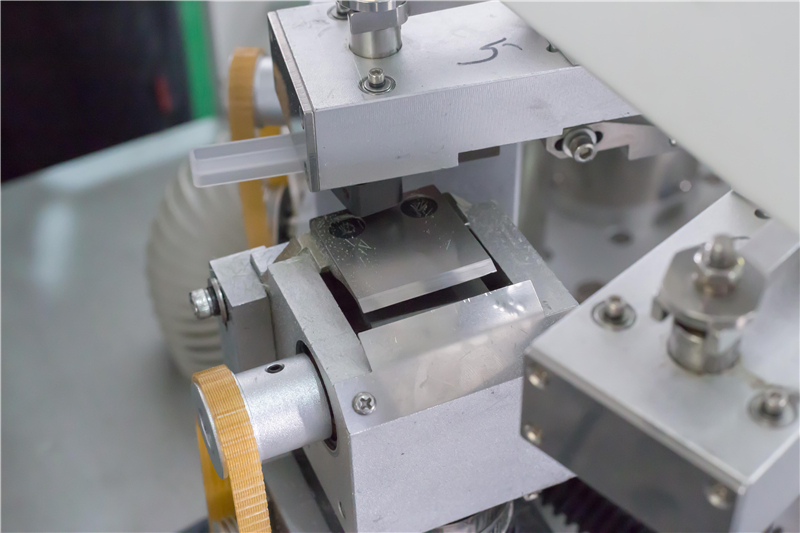

Part Of Square Hole

Feature: 1. Can produce square hole type brush, conventional brush more versatile

2.Adjustable mechanical structure design, convenient and quick adjustment.

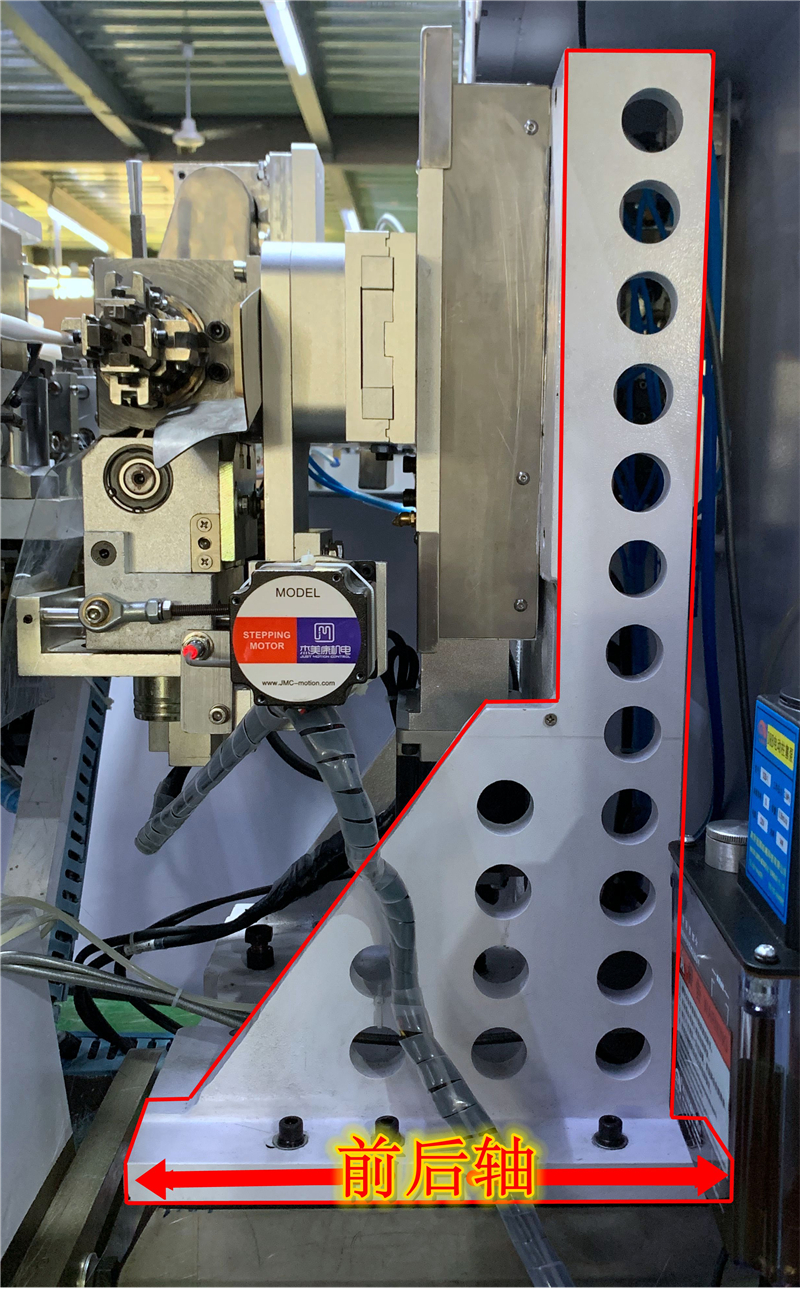

A Curved Part

Feature: 1. Casting process, to eliminate the internal stress caused by equipment vibration, so as to ensure the accuracy of repeated positioning.

2. The mechanical mechanism of the working table is designed inside the L-shaped castings, which is more reasonable, so that its load-bearing force is more powerful than that of a merchant designed outside the L-shaped castings.

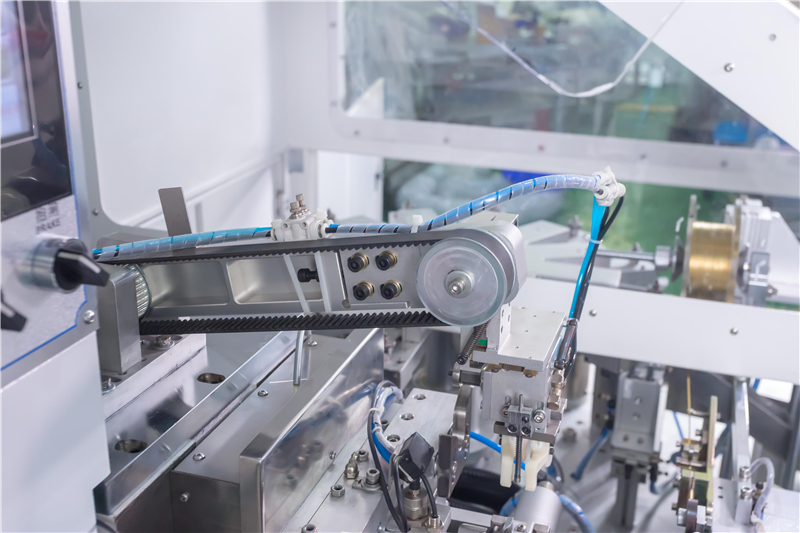

Manipulator: 1. Rocker Arm

Feature: Rocker arm design, 50% faster than the conventional guide rail speed, fast adjustment

Manipulator: 2. Finger Clip

Feature: The toothbrush head is designed to be more stable. The toothbrush with large deformation is not easy to clamp the handle to increase productivity.

Grinding: 1. Mechanical Connecting Arm

Feature: The mechanical arm (connect from tufiting to grinding) saves the cost of the production and operation of the equipment, and it is easy to adjust and replace the machine.

Grinding:2. Timming Device

Feature: Double trimming design in the grinding process, suitable for various shapes of designed products

Grinding Head

Feature: Eighth-grade all-directional positive and negative dimensional swing type and imported diamond grinding disc, so that the ratio of grinding filament grinding round is more than 90% higher than the national standard

Dust Removal Device, Electrostatic Removal Device

Feature: Auto design for dust removal device, electrostatic removal device.

Product detail pictures:

Related Product Guide:

We insist about the theory of growth of 'High excellent, Performance, Sincerity and Down-to-earth working approach' to offer you with great company of processing for Manufacturer for Tool Grinding Machine - Automatic Tufting and Trimming Machine with All-in-one – Chuangyan , The product will supply to all over the world, such as: Austria, San Diego, Maldives, We have advanced production technology, and pursuit innovative in goods. At the same time, the good service has enhanced the good reputation. We believe that as long as you understand our product, you need to be willing to become partners with us. Looking forward to your inquiry.

In our cooperated wholesalers, this company has the best quality and reasonable price, they are our first choice.

+86754-87916365

+86754-87916365

.png) 13342756672

13342756672