Products

One of Hottest for Pneumatic Sheet Cutting Machine - High Efficiency Injection Molding Machine for Toothbrush – Chuangyan

One of Hottest for Pneumatic Sheet Cutting Machine - High Efficiency Injection Molding Machine for Toothbrush – Chuangyan Detail:

Main Application

This equipment is used for injection molding of toothbrush. It is the process of injecting the plasticized molten plastic into the closed mold cavity with the help of the thrust of the screw, and obtaining the product after curing and shaping. The injection molding machine is capable of forming plastic products with complex appearance, precise size or dense texture with metal inserts at one time. It can imitate part of the function of the human upper limb, can be automatically controlled to make it in accordance with the scheduled requirements of conveying products or operating tools for production operations of automatic production equipment.

Introduction

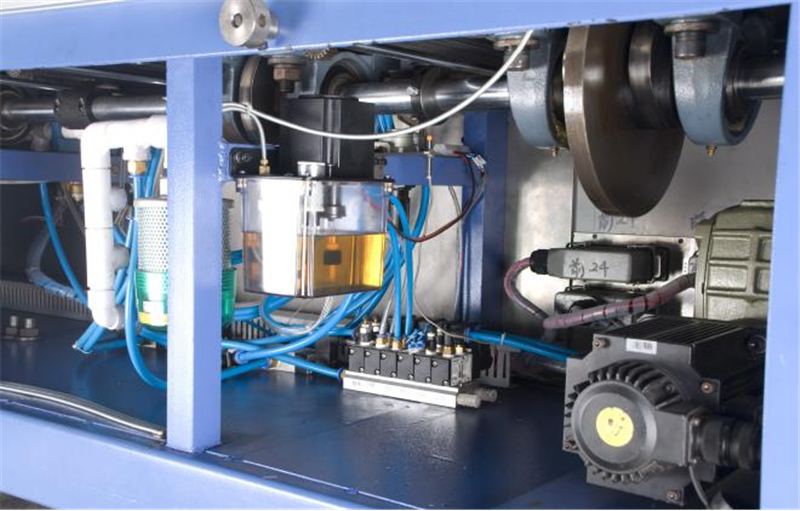

● The use of excellent performance servo controller, servo motor and other energy-saving devices

● Sensitive servo control system, quick start and short reaction time

● Due to the low body of the injection molding machine, the material is convenient and the maintenance is easy

● The whole operation has low noise, which not only benefits the workers, but also reduces the investment and construction cost in the soundproof production workshop

Detail Information

| Screw diameter: 42mm | Opening stroke: 435mm |

| Screw L/D ratio: 23.8L/D | Space between tie bars: 470x470mm |

| Cylinder head volume: 290.8ml | Mould thickness: 180-520mm |

| Injection weight: 264.6g | Injector stroke: 140mm |

| Injection pressure: 206.3Mpa | Injector force: 53KN |

| Injection speed: 99mm/s | Injector number: 5 piece |

| Injection stroke: 210mm | Servo motor power: 18.7KW |

| Screw speed: 202r/min | Heating capacity: 10.5KW |

| Clamping force: 1780KN | Heating section: 3+1 |

Detail Information

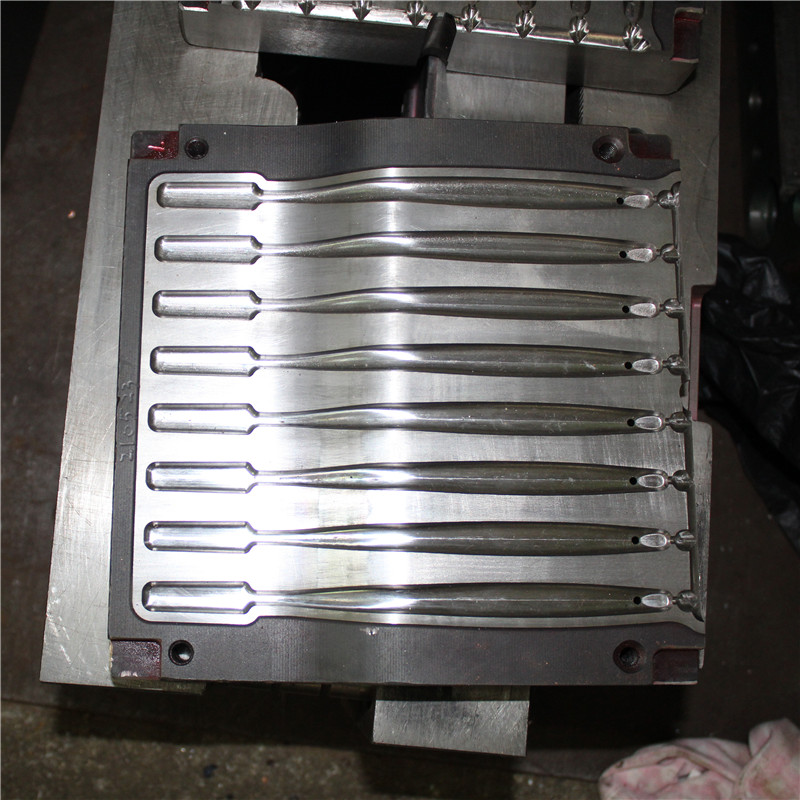

Main Transmitting Shaft

Feature: 1. Synchronous positioning, high precision

2. High torque, high stability, low wear and tear, low noise

Product detail pictures:

Related Product Guide:

With dependable high-quality method, fantastic standing and ideal purchaser assistance, the series of products produced by our firm are exported to many countries and regions for One of Hottest for Pneumatic Sheet Cutting Machine - High Efficiency Injection Molding Machine for Toothbrush – Chuangyan , The product will supply to all over the world, such as: Guyana, Provence, Estonia, We maintain long-term efforts and self-criticism, which helps us and improvement constantly. We strive to improve customer efficiency to save costs for customers. We do our best to improve the quality of product. We will not live up to the historic opportunity of the times.

It is really lucky to meet such a good supplier, this is our most satisfied cooperation, I think we will work again!

+86754-87916365

+86754-87916365

.png) 13342756672

13342756672