Products

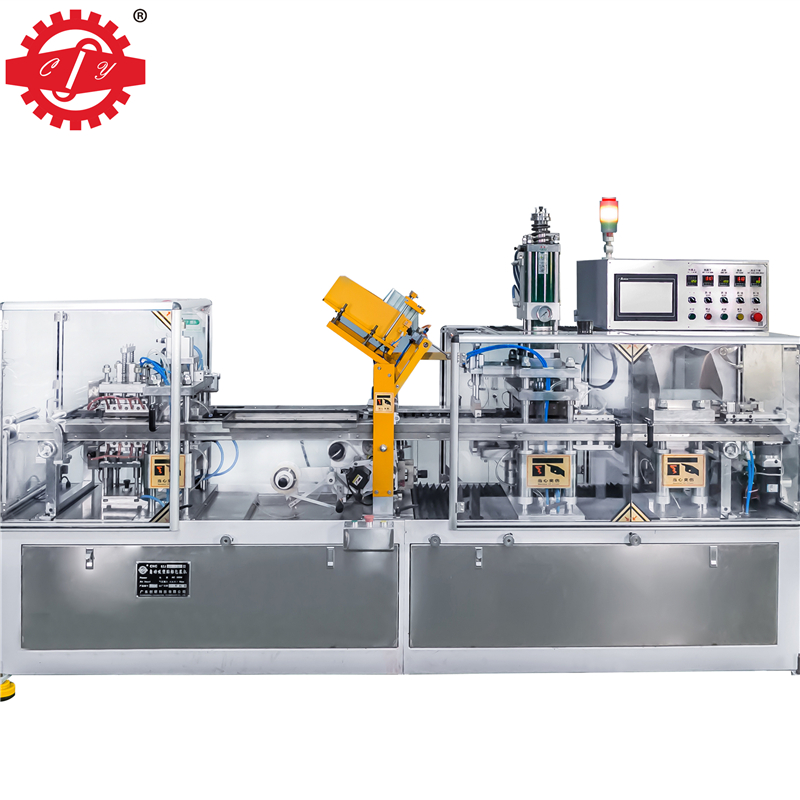

Top Quality Pneumatic Sheet Metal Cutter - Automatic Blister and Labeling Packaging Machine – Chuangyan

Top Quality Pneumatic Sheet Metal Cutter - Automatic Blister and Labeling Packaging Machine – Chuangyan Detail:

Introduction

Based on former toothbrush packing technology from Korea Xinye and German. According to the new toothbrush products in the market, a new automatic toothbrush blister labeling and packaging machine has been developed by self-innovation. Accepted in the market, this equipment has been certified by Chinese authoritative organizations and has become the equipment of “Chinese scientific and technological innovation and invention achievement”. This machine applies full sevo double CAM with one transmitting shaft and double stage servo chain clamp,servo pulling and lebeling,auto feeder cardboard,heating cutting synchronously. The working steps are controlled by PLC.

Specification

|

Machine Data |

Technical parameters |

| Machine dimensions: 3980mmX1068mmX1948mm |

Speed: 15-20 times/min |

| Case dimensions: 4000mmX1200mmX2050mm |

Forming length: 195MM-250MM |

|

Case1: 185mmX108mmX195mm |

Forming width: 20MM-190MM |

|

2Case2: 235mmX78mmX166mm |

Max forming depth: 40MM |

|

Net weight: 1850KG |

Max stamped length: 80MM |

|

Gross: 2100KG |

Sheet material: PVC/PET |

|

Electric supply: three-phase four-wire 380V 50-60Hz |

Thickness of sheet: 0.15MM-0.5MM |

|

Electric switch power: 64A or more |

Material of cardboard: White board card, copper card, laser card |

|

Total max power: 14.11KW |

Cardboard thickness: 250-500 gram |

|

Running power: 4.2KW |

No. for Oil pressure cylinder: No.60 hydraulic oil |

|

Air compressor: 0.65MPa |

No. for oil box: CC40 model |

|

Input air tube: 12MM |

No. for gear box: CKD220 model |

|

Air consumption: ≥1㎡/MIN |

Equipment utilization: Refer to technology document No.2 |

|

Cooling water: Pure water |

Noise: 60 db |

|

Water temprature: 10-22 degrees |

Cooling water consumption: Refrigeration circulation cooling water |

|

Input water tube: 12MM |

Detail Information

Main Transmitting Shaft

Structure: Servo double CAM connected spindle structure

Feature: 1. Synchronous positioning, high precision

2. High torque, high stability, low wear and tear, low noise

Plastic Uptake Forming

Structure: Pneumatic sliding block fixed positioning type

Feature: Blister forming, accurate positioning accuracy, compact structure, less gas consumption,Easy mold replacement

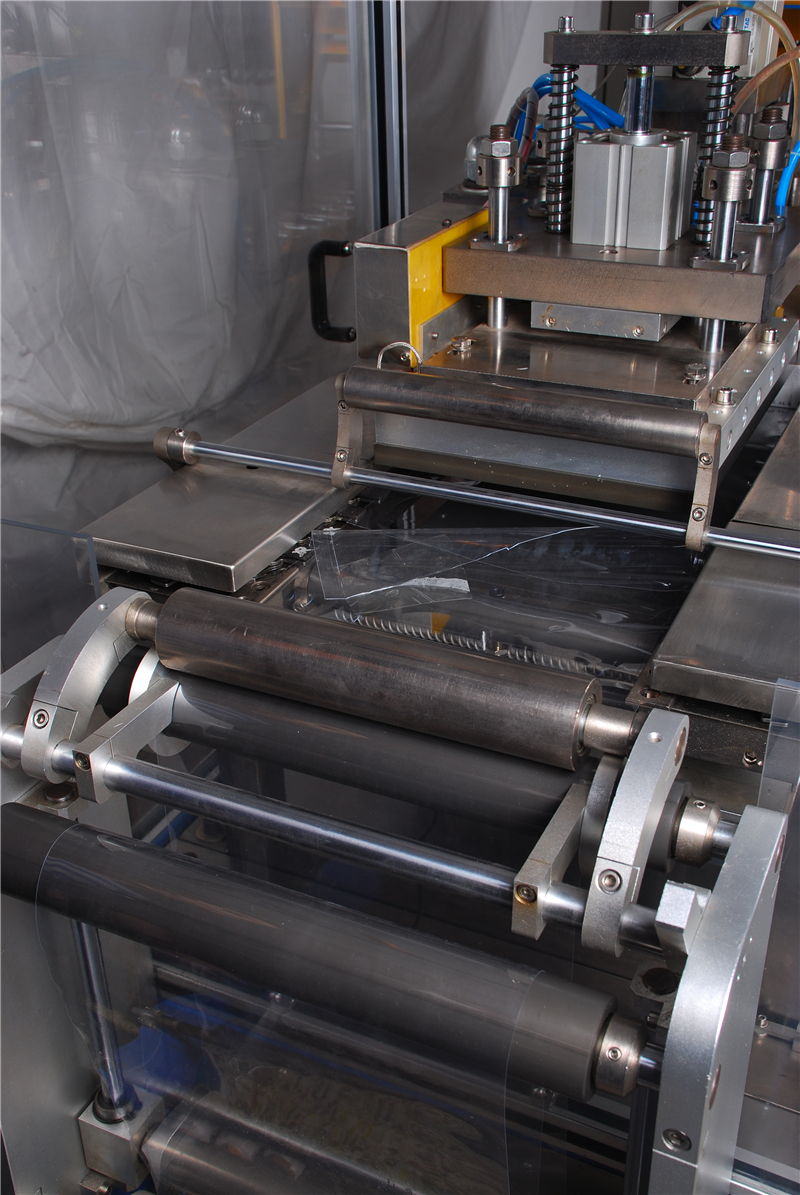

Sheet Pulling

Structure: Chain clip pulling sheet by servo

Feature: Stable pulling sheet, accurate positioning, precision tolerance ± 0.2mm, adjustable stroke, no-delay pulling

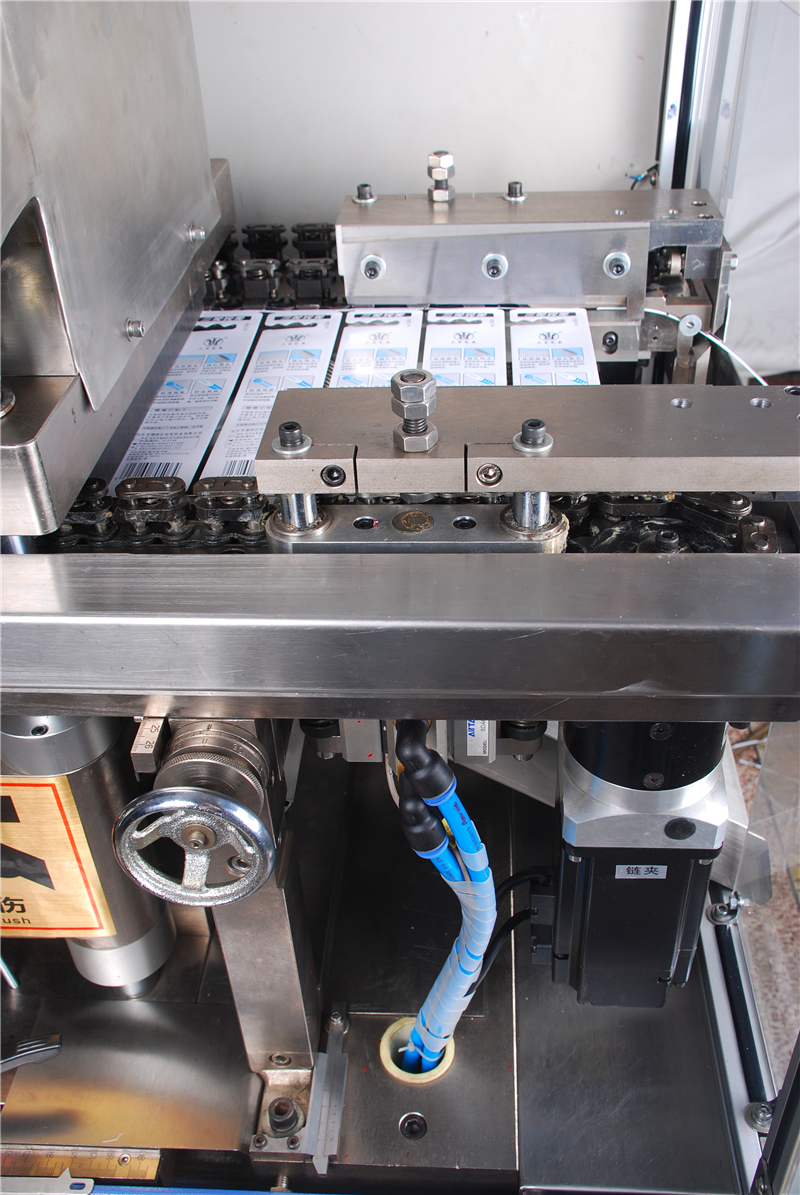

Heating Forming

Structure: Adopt heat sealing adjustable liquid pressurized cylinder type

Feature: Good heat sealing effect, good flatness, high efficiency, cardboard thickness adjustable easy

Cutting

Structure: Double CAM cutting structure

Feature: 1. low cost of mould, easy replacement,small cutting press,low noise

2.Function station product specification control by dividing rule

Labeling

Structure: Servo drive,up-stamped

Feature: Labeling stable positioning, high precision, front, back, left, right, up and down three axes adjustable, easy operation for re-change labeling film

Waste Sheet Of Cutting

Structure: Auto push waste sheet

Feature: 1. Easy operation, small space, high production efficiency, low shutdown rate, strong adjustable, no manual move waste sheet

2. Help for choose automatic card matching equipment in coming working procedure plan

Feeder Cardboard

Structure: Special scan detection

Feature: 1. Cardboard can be high resolution, will not cause thermal bonding mold

2. possible for multilayer cardboard aredetachable

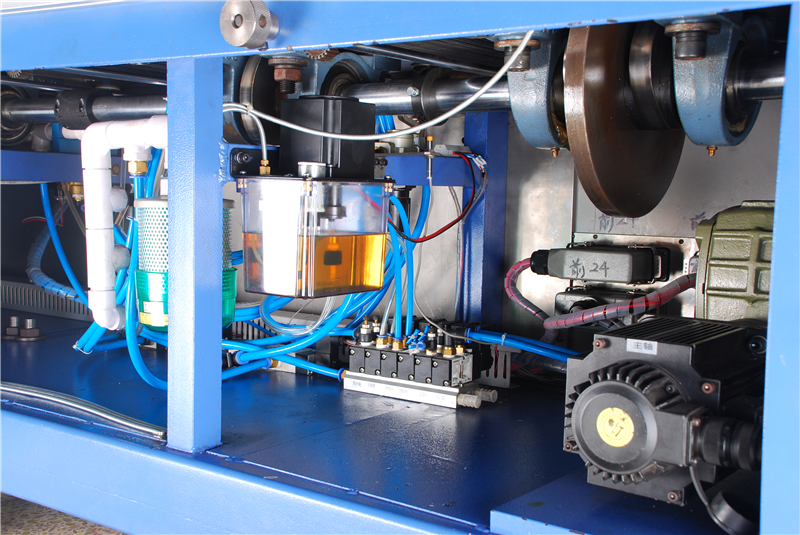

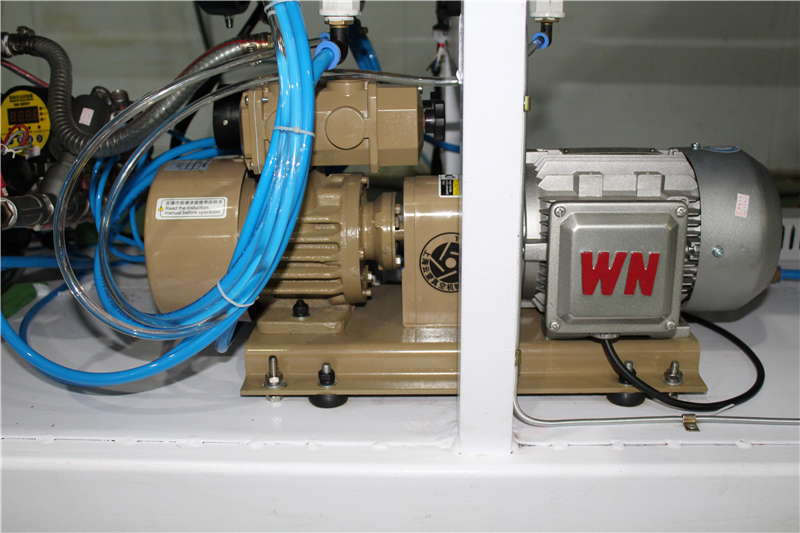

Vacuum, Air, Oil Pipeline

Structure: Import cylinder, solenoid valve, oil-free vacuum pump

Feature: Strong stability, high frequency of use, long life, smokeless, low noise, large vacuum force, high safety, suitable for environmental protection workshop use

Circuit

Structure: Stepless servo speed control, high and new imported numerical control code and PLC programmable, touch screen operation and control mode, digital display heating module

Product detail pictures:

Related Product Guide:

Our company since its inception, constantly regards product or service high quality as business life, continually improve creation technology, make improvements to product high-quality and consistently strengthen business total high-quality management, in strict accordance together with the national standard ISO 9001:2000 for Top Quality Pneumatic Sheet Metal Cutter - Automatic Blister and Labeling Packaging Machine – Chuangyan , The product will supply to all over the world, such as: Johannesburg, Algeria, Lesotho, We taking advantage of experience workmanship, scientific administration and advanced equipment, ensure the product quality of production, we not only win the customers' faith, but also build up our brand. Today, our team is committed to innovation, and enlightenment and fusion with constant practice and outstanding wisdom and philosophy, we cater to the market demand for high-end products, to do professional products.

The sales manager has a good English level and skilled professional knowledge, we have a good communication. He is a warm and cheerful man, we have a pleasant cooperation and we became very good friends in private.

+86754-87916365

+86754-87916365

.png) 13342756672

13342756672